- +86 15014663482

- [email protected]

With its modern melting technology, the JC group company has influenced the industry in recent years. Melting furnaces from JC are characterized by energy efficiency and a high metal yield. The key figures for “green” aluminium melting. The heating system is either based on gas or more ecological by electricity.

JC group products include innovations for single-chamber furnaces, multi-chamber furnaces and Universal Rotary Tilting Furnaces (URTFs), but also chip remelting plants and scrap charging machines.

Together with casting and heat treatment lines as well as quality inspection and sawing- packaging equipment, we offer an automated plant concept for the entire production process: the Compact Type Remelt Plant (CTRP) – from scrap to billet.

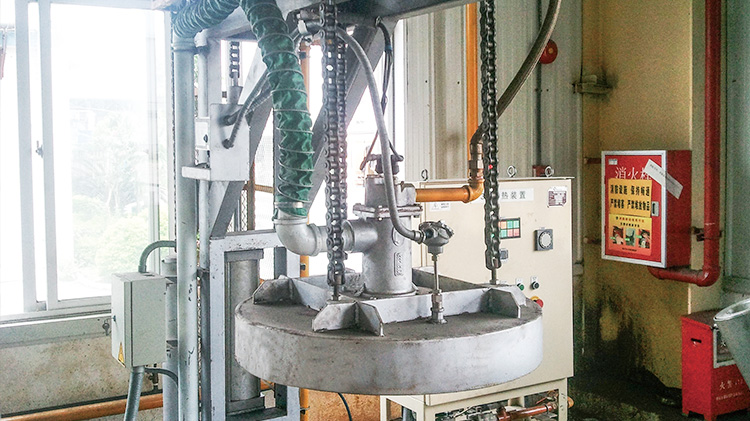

It is suitable for ladle for transportation of molten aluminum between the dissolution plant and other foundry plants. The lining material of the transfer bag is a non-stick aluminum light-weight castable, which has the characteristics of non-stick aluminum and small heat loss. The inner liner is coated with boron nitride surface fixative

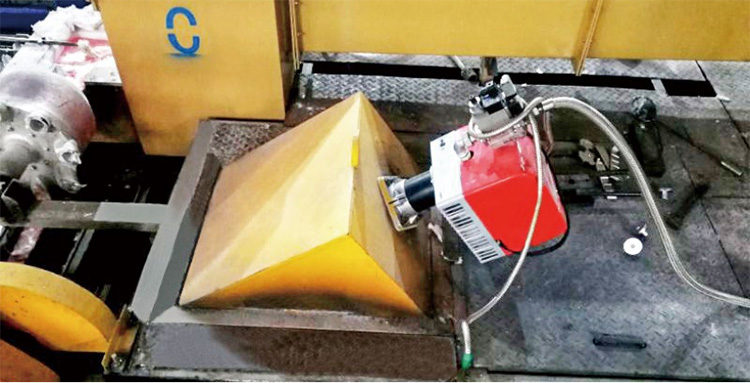

Suitable for the preheating of aluminum liquid transfer bag, this product is independently designed with combustion safety device and automatic interlocking system. The automatic ignition and flame detection device means that after the device has the operating conditions, it is first blown and purged, then the main burner is automatically ignited through the ignition transformer, and the flame detection device automatically detects the flame.

Simple operation, with overpressure protection device, safe and reliable.

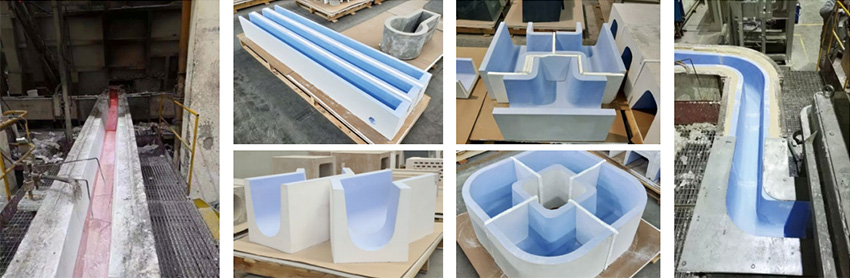

The flume / filter box mainly uses high-quality non-stick aluminum casting material, which is suitable for long-term contact with high-temperature liquid aluminum, and has the properties of high density, high strength and non-wetting for aluminum and alloy. Product manufacturing process requirements are strict, widely used in the Non-ferrous metal industry, according to the different requirements of customers on site, the design of more reasonable aluminum flume system.

JC melting furnaces are characterized by energy efficiency and high metal yield. These are the key principles we apply to design JC melting furnaces, yet we adapt the detail engineering to meet your specific requirements.

supplied by JC GROUP

supplied by JC GROUP

For more information kindly get in touch via the contact form and mention the product you are interested in.

It is suitable for ladle for transportation of molten aluminum between the dissolution plant and other foundry plants. The lining material of the transfer bag is a non-stick aluminum light-weight castable, which has the characteristics of non-stick aluminum and small heat loss. The inner liner is coated with boron nitride surface fixative, which enhances the resistance to aluminum water erosion. The internal heat insulation material will not adversely affect the quality of the aluminum liquid during the aluminum liquid handling process. The unique tightening sealing device ensures that the tilted aluminum liquid of the package body does not leak and has high safety. Suitable for the preheating of aluminum liquid transfer bag, this product is independently designed with combustion safety device and automatic interlocking system.

The automatic ignition and flame detection device means that after the device has the operating conditions, it is first blown and purged, then the main burner is automatically ignited through the ignition transformer, and the flame detection device automatically detects the flame. The safety system can immediately interrupt the gas supply when the burner is not completely burned or extinguished. And there is an interlocking device between the gas and air line pressure switch, so that when any combustion conditions are abnormal, the fuel supply shut-off valve can be driven by the reaction of the interlocking device.

Suitable for the preheating of aluminum liquid transfer bag, this product is independently designed with combustion safety device and automatic interlocking system. The automatic ignition and flame detection device means that after the device has the operating conditions, it is first blown and purged, then the main burner is automatically ignited through the ignition transformer, and the flame detection device automatically detects the flame.

The safety system can immediately interrupt the gas supply when the burner is not completely burned or extinguished. And there is an interlocking device between the gas and air line pressure switch, so that when any combustion conditions are abnormal, the fuel supply shut-off valve can be driven by the reaction of the interlocking device.

Online dryer

Online degassing device

Nitrogen making machine

Aluminum liquid hydrogen tester

Permanent magnetic stirrer