- +86 15014663482

- [email protected]

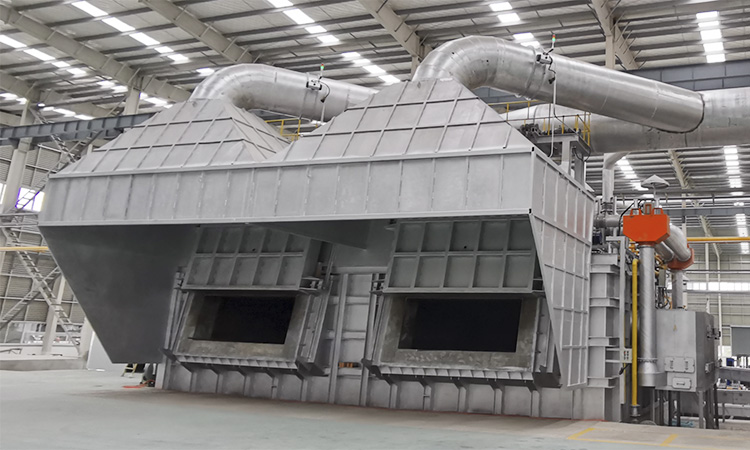

With its modern melting technology, the JC group company has influenced the industry in recent years. Melting furnaces from JC are characterized by energy efficiency and a high metal yield. The key figures for “green” aluminium melting. The heating system is either based on gas or more ecological by electricity.

JC group products include innovations for single-chamber furnaces, multi-chamber furnaces and Universal Rotary Tilting Furnaces (URTFs), but also chip remelting plants and scrap charging machines.

Together with casting and heat treatment lines as well as quality inspection and sawing- packaging equipment, we offer an automated plant concept for the entire production process: the Compact Type Remelt Plant (CTRP) – from scrap to billet.

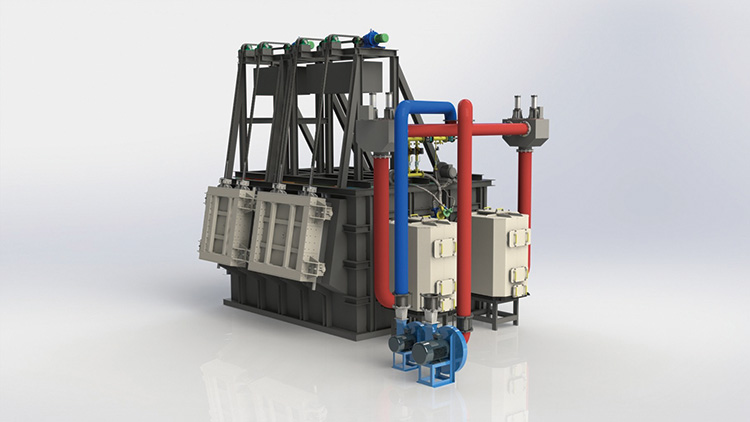

It can tilt and flip, and this furnace type belongs to high-end industrial furnaces, suitable for user enterprises with high requirements for aluminum liquid quality.

Pouring is more convenient, as the furnace body can tilt, the aluminum liquid in the furnace can be poured into the pouring machine through the tilting of the furnace body, making this process more convenient.

JC melting furnaces are characterized by energy efficiency and high metal yield. These are the key principles we apply to design JC melting furnaces, yet we adapt the detail engineering to meet your specific requirements.

supplied by JC GROUP

supplied by JC GROUP

For more information kindly get in touch via the contact form and mention the product you are interested in.

The method for preparing aluminum alloy round ingots by this equipment product includes: melt treatment process, air curtain casting process, homogenization annealing process, which relates to the technical field of aluminum alloy preparation, in particular to a large diameter aluminum alloy round ingot and its preparation method .

The method for preparing aluminum alloy round ingots by this equipment product includes: melt treatment process, air curtain casting process, homogenization annealing process, which relates to the technical field of aluminum alloy preparation, in particular to a large diameter aluminum alloy round ingot and its preparation method .