- +86 15014663482

- [email protected]

With its modern melting technology, the JC group company has influenced the industry in recent years. Melting furnaces from JC are characterized by energy efficiency and a high metal yield. The key figures for “green” aluminium melting. The heating system is either based on gas or more ecological by electricity.

JC group products include innovations for single-chamber furnaces, multi-chamber furnaces and Universal Rotary Tilting Furnaces (URTFs), but also chip remelting plants and scrap charging machines.

Together with casting and heat treatment lines as well as quality inspection and sawing- packaging equipment, we offer an automated plant concept for the entire production process: the Compact Type Remelt Plant (CTRP) – from scrap to billet.

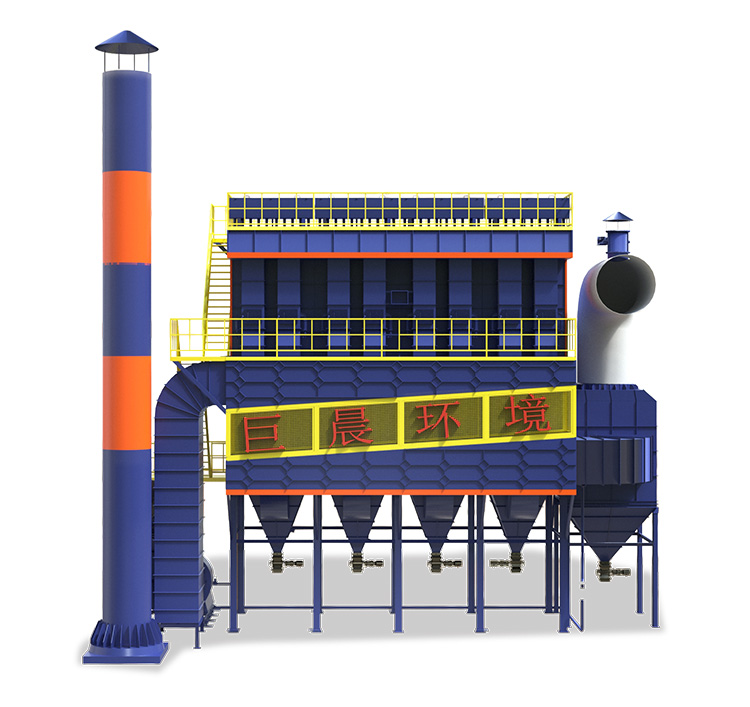

Dust containing gas from the branch pipe into the pipeline into the cydone dust collector, filter out a part of the coarse partidles and then into the bag filter entrance, from Precipitator inlet into the hopper due to the gravity of the dust, coarse partidles under the action of gravity, direct sttlement in the funnel. The rest of the dust laden gas is raised to the In the box, evenly distributed in each bag. When the dust is blocked in the outer surface of the bag, after being fltered clean gas through a bag flower

The smoothness of the surface of the filter material has a great influence on the dynamic running resistance of the filter material. The initial resistance of the filter material depends on the permeability of the filter material itself, and the resistance during operation is many times greater than the initial resistance. The running resistance depends on The smoothness of the surface of the filter material, t

JC melting furnaces are characterized by energy efficiency and high metal yield. These are the key principles we apply to design JC melting furnaces, yet we adapt the detail engineering to meet your specific requirements.

supplied by JC GROUP

supplied by JC GROUP

For more information kindly get in touch via the contact form and mention the product you are interested in.

The smoothness of the surface of the filter material has a great influence on the dynamic running resistance of the filter material. The initial resistance of the filter material depends on the permeability of the filter material itself, and the resistance during operation is many times greater than the initial resistance. The running resistance depends on The smoothness of the surface of the filter material, the cleaning effect, etc., generally hope that the filter material ensures the same filtration efficiency, the greater the air permeability, the lower the resistance, the better.

In the dust removal equipment that uses airflow to blow back the cleaning, the same When cleaning the air with pressure and the same air volume, it is better to choose a woven fabric with a large air permeability as the filter bag than a woven fabric with a small air permeability.